- Drivers Sealed Unit Parts Port Devices List

- Drivers Sealed Unit Parts Port Devices Gigabit

- Drivers Sealed Unit Parts Port Devices For Sale

- Drivers Sealed Unit Parts Port Devices Inc

Price: $199.95 The PLX Kiwi Drive Green is an efficiency driving coach that uses a stand-alone display and plugs into your car's OBD-II port using a cord. The device opens up a large menu of.

- W0v3 12-inch Subwoofer (300 W, 4 Ω)The 12W0v3 is a rugged performer with excellent efficiency, excursion capability and linearity. Its overall performance envelope that puts it right at the top of its price class. It features a beefy 2 in. Diameter voice coil and our patented Elevated Frame Cooling design for enhanced power handling and reliability.The 12W0v3 is best used with amplifier power.

- The drivers used in today’s “sealed” subwoofers are not acoustic suspension drivers. The majority of the restoring force is not provided by the air spring in the subwoofer’s enclosure, as would be the case in a true acoustic suspension system using a very high-compliance driver.

There are lots of great ported subwoofers and full-range towerspeakers from many great companies that come with “port plugs” so the user canblock up the ports and turn these systems into “sealed” systems. Many oftoday’s audio enthusiasts make the mistake of thinking that these newly-sealedspeakers are now bonafide sealed systems and that their performance is nowrepresentative and indicative of what sealed loudspeakers are all about.

That’s not true. In fact, nothing could be farther from thetruth. A ported speaker with its ports sealed off is a strange mutation that isneither fish nor fowl: It no longer performs like the vented speaker it wasdesigned as, nor is it a properly-executed sealed speaker. It is an aberration,a nothing. There may be some understandable reasons you might want to do thisunder very specialized conditions (which we’ll touch upon later), but in themain, sealing a vented speaker does not create a proper sealed-box system.

But first, some historical context.

The History of AcousticSuspension

With all due apologies to Gene Roddenberry, audio enthusiasts definitelyseem to rally around the thought of, “Bass—The Final Frontier.” The crusade forbetter bass response has been an ongoing quest of audiophiles since the veryearliest days of this hobby. In the late 1940’s/early 1950’s—right after theend of World War II in 1945—‘hi-fi’ audio became a major hobby and pastime inAmerica. As millions of returning GIs got married, raised their families andbought houses in the newly-burgeoning suburbs that were springing up everywhere,home music systems took their place alongside television as the staples of homeentertainment electronics.

Those very early post-war home music systems were not exactlybarn-burners of wide-range, accurate reproduction. They were mono systems(single channel), comprised of tube electronics of limited power and bandwidth.Ten or twenty watts maximum was common, with a frequency range of about 50 or60-15,000 “cps” (cycles per second, as it was called then). THD at maximumpower, if it was specified at all, was usually on the order of 10%, especiallyin the bass end.

1950’smono music system

But, a low-end limit of 50 or 60 Hz was just fine in 1951because the vast majority of home loudspeakers couldn’t reach any lower thanthat anyway. Speakers in those days were typically some sort of bass-reflex orinfinite-baffle design, woofers that had some kind of accordion/pleatedsurround and a very stiff, low compliance suspension system. Names likeUniversity, Bozak, Jensen, Electro-Voice and others dotted the scene.

Many people didn’t even buy commercially-designed andmanufactured finished speakers. Instead, a lot of music consumers simplyinstalled raw, standalone speakers (perhaps full-range drivers with a ‘whizzercone’ to extend the response a bit or an actual coaxial design) into walls orcloset doors by cutting a circular hole in the hollow-core wood door andmounting the speaker. When the closet door was closed, the “enclosure” wasready to go. That’s really the way it was done. Today’s rabid home theateraficionados, meticulously positioning their 7.2.4 Dolby Atmos speaker system,aided by sophisticated digital Audyssey room-correction EQ, undoubtedly have ahard time believing this is how it once was. But it’s true.

1950’sStaples: Full-range speaker with whizzer, infinite-baffle co-ax

In order to reach down to even to 40 or 50 Hz, the best speakersof that time had to be huge, refrigerator-sized infinite baffle designs withmultiple woofers or big ported or horn-loaded speakers. The Bozak Concert Grandused four (4) 12-inch woofers and a line array of cone tweeters in a mammoth box inorder to reproduce what it could of the full musical frequency range. TheConcert Grand series—made from around 1951 until the mid 1970’s—was emblematicof those huge top-of-the-line speakers from audio’s early years.

But then something remarkable happened in the home-musicreproduction realm: Stereo was invented. Now, everything would be two channels,not one. Left, right and a phantom “center” channel. Imaging. Left-rightpanning. Three-dimensionality. Depth. Two channels opened up the concept of thelifelike soundstage in home listening, in a way that single-channel (mono)systems never could.

Two-channel stereo was indeed a great advancement in the realismand enjoyment that could now be attained from a home music system. Unfortunately,however, one of those refrigerator-sized monstrosities was difficult enough tosqueeze into the typical family room of a 1950’s split-level home on Shady Lane.Two of those speakers (for stereo) would be absolutely out of the question.Impossible.

Qube driver download for windows 10. Refrigerator-sized Bozak Concert Grandspeaker

Quite fortunately forus, an enterprising young inventor named Edgar Villchur had an idea for gettingsolid, extended low-distortion bass from an enclosure barely 1/8 the size ofthe best existing speakers. Although not a formally-trained acoustics engineer,Villchur was one smart, savvy individual. He looked at the current loudspeakersof the day and saw that their cone’s motion (the so-called “restoring force”that brought the cone back to its original resting position once the inputsignal had ceased) was controlled by that speaker’s suspension—the surroundaround the outside of the cone and the pleated “spider” that centered andsupported the voice coil. Together, these two components were responsible formost of the cone’s control as it traveled back and forth in response to theinput signal. Because of their suspension design and the requirement that thesuspension exercise such tight control over the cone’s motion, these drivershad a very low compliance (the driver moved stiffly back and forth). Mathematically,in Thiele-Small parlance (language that wouldn’t be commonly spoken in theloudspeaker universe until the early ‘70’s, almost 20 years into the futurefrom the time of these speakers), these low-compliance drivers are known ashaving a high total Qts, usually well above .4 or so.

Villchur saw theinherent limitations that a man-made suspension had on driver control. Both theedge surround and the spider were subject to fairly significant unit-to-unitvariations, manufacturing irregularities, material inconsistencies,labor/assembly errors and so on. Villchur found a better way..

Air.

He used air as therestoring force for the driver’s cone, not a mechanical man-made suspension.Air is “perfect” from an engineering standpoint, because it behaves in anabsolutely predictable, consistent manner and there are no unit-to-unitvariations or manufacturing irregularities. In order for air to supply thecone’s restoring force, it has to be “springy” enough to bounce back, if youwill, when it’s compressed. The nice thing is that it will do so withessentially perfect linearity.

So Villchur designed adriver with the opposite characteristics from the drivers that existed at thetime, in the very early 1950’s. His driver would have extremely high compliance(a low Q driver). The edge surround and spider would merely hold the conephysically in place, but they would not exert dominant control over the cone’smotion. The air spring trapped inside of the sealed cabinet would do that. Asthe driver moved, the enclosure’s air spring would control its motion, with fargreater linearity and lower distortion than the mechanical suspension of aconventional speaker.

By adjusting thedriver’s mass (thus raising or lowering its free air resonance or FAR), thestrength of the magnetic field around the voice coil and making the enclosureslightly bigger or smaller to maintain the proper air spring, the designercould achieve a desired low-frequency extension for his particular design goal.The famous “Hoffman’s Iron Law” was always in play (LF extension, sensitivityand smaller enclosure size—pick any two at the expense of the third), butwithin reason, a designer could obtain strong, deep bass response with very lowdistortion in an enclosure 1/8 the size of a Bozak Concert Grand.

Note:Hoffman's Iron Law stated you could you could only have 2 of the 3 in relation to bass in loudspeakers: 1) Bass Extension, 2) Efficiency, and 3) Small Enclosure

Acoustic Suspension Enclosures

Villchur’s “acoustic suspension” design madeit possible to get truly accurate, powerful bass into the low 30 Hz-range froma cabinet that was only about 1.5 cu ft in volume—only 25 x 14 x 11” deep.Truly a “bookshelf” speaker. Any normal-sized room could easily accommodate twoof his AR-1 speakers, and their bass response was superior to thoserefrigerator-sized dinosaurs—tighter, cleaner, more extended.

AR quickly introduced smaller, less expensive versions of their first model andother companies followed suit, so good-sounding compact speakers that could beused in pairs in any room became readily available and affordable at the sametime that solid-state stereo electronics with reliable silicon transistorsbegan to really take off. AR wasfollowed quickly by the KLH Corporation, and then by Advent and EPI, alloffering compact speakers utilizing the acoustic suspension design principle oflow-frequency loading. These were meticulously-engineered speakers, with theirdesigners—long before the days of instantaneous computer simulations workingthrough thousands of iterations—painstakingly jockeying woofer parameters,enclosure size, cabinet stuffing schemes, etc., all in a frantic competitiveeffort to wring an additional 3 or 4 Hz of bass extension while maintainingacceptable efficiency and impedance characteristics at a given price point.

If thehigh-performance bookshelf speaker as pioneered by Villchur’s AR-1 hadn’t beenavailable right at the beginning of the stereo era, the market would likelyhave developed quite differently.

AR-3 bookshelf loudspeaker from 1958 - image courtesy of Tom Tyson

In the 1960’s thru the1990’s. audio stores were commonplace. Stores that specialized in the displayand demonstration of “stereo equipment” seemed to be everywhere and they featured“speaker walls,” where customers could choose any two sets of speakers and thestore salesman would perform instantaneous comparisons, switching rapidlybetween the two while the music played. These stereo store showroom “A-B”comparisons ruled the day. When a 19-year-old student from Boston Universitywandered into Tech Hi-Fi with his favorite Emerson, Lake and Palmeralbum under his arm, the $125 ea. speaker that had the strongest bass line on“Lucky Man” would win the day—and the dollars. A -3dB down point of 46 Hz or 41Hz could make the difference. In those days, speaker engineers didn’t have theluxury of on-board, high-powered amps that could be EQ’d at will to achieve adesired LF extension and response shape. In the 1960’s thru ‘90’s, speakerengineers got their speakers to reach their design goals “organically”—inresponse to a flat-response external signal input, not with internal EQ thatcould wallpaper over design errors, laziness or lack of fundamental design understanding.

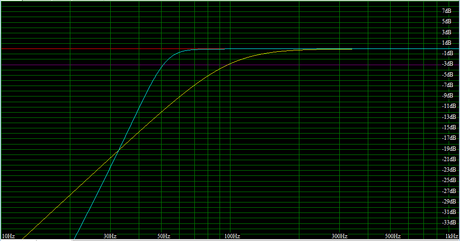

Acoustic suspensionheld some other advantages over vented designs as well. For one, a sealed boxrolls off at 12dB/oct below the system resonance. In contrast, a vented systemdrops off the cliff below its tuning frequency at 24 dB/octave, so there isgenerally more usable low bass in a passive acoustic suspension system than ina passive vented system, below their respective -3 dB points. In addition,because of the linearity and predictability of the trapped air in aproperly-designed acoustic suspension system, its transient response tends tobe better and above the system’s resonance, its THD is usually lower. Groupdelay is also better in an acoustic suspension speaker than in a vented one.

Sealed Rolloff (12 dB/oct, yellow) vs. Vented Rolloff (24 dB/oct, blue)

Bass Reproduction & Group Delay

Therewas an intriguing article by the late Peter Mitchell in the December 1995 issueof Stereo Review on the subject ofgroup delay in loudspeakers. Group delay is a measure of how sharply the phaseof a signal changes with frequency. Mitchell was an acclaimed audio expert,reviewer, and commentator whose views and writings were very highly regarded.He was a founding member of the nationally-known Boston Audio Society. Iremember he caused quite a stir at a Bose press conference several years agowith his pointed, relentless questioning and was summarily banned from allfuture Bose press events. His passing several years back was quite a loss forthe audio enthusiast community.

Inthis article, Mitchell puts forth the idea that there is a definite correlationbetween the subjective quality of bass reproduction and superior group delayperformance. Speaker systems can be thought of as minimum-phase filter devices,so the magnitude response (amplitude vs. frequency) of a speaker will determineits phase, time (impulse) and group delay characteristics. All things beingequal, sealed speakers (2nd -order high pass filters) have superior (lower)group delay characteristics than ported or bandpass systems (4th - or 6th-order high pass filters). As Mitchell’s article states, “Sealed-box…speakersystems consistently have the least group delay (under 10 milliseconds), andthey usually deliver the tautest bass transients, the deepest-sounding basstones, and the most clearly resolved bass textures. Bass reflex and bandpasssystems often exhibit substantial group delay [in excess of 50milliseconds]…and their sound tends to be thicker, fuller, and ‘slower’.”

Thisis very thought-provoking, and goes a long way to explaining why the “tightnessand crispness” of the bass of an acknowledged “perfectly done” acousticsuspension system like the classic AR-3a, or AR-9 with dual 12-inch woofers seemsso much better than many other systems’.

AR-3a withFR of -3dB at 35 Hz

Note,however, that there are lots of factors that are not “equal.” The systemdesigner has many choices. How he chooses to damp the system affects themagnitude response, and thus affects all the other factors, including groupdelay. An under-damped sealed system will exhibit poorer group delaycharacteristics than a properly-damped ported system.

Withthe advent of computer design and instantaneous iterative testing, it’s routinethese days for skilled engineers, armed with precise Thiele-Small parametersthat didn’t exist in the 1950’s and 60’s, to deliver vented systems thatmaximize all of that design approach’s theoretical advantages while minimizingtheir drawbacks. Early vented systems got an undeserved bad rap for being boomyand inaccurate mostly because speaker designers had to try every variation ofvent tuning, driver characteristic and enclosure size in real time, creating anew physical prototype each time they wanted to try something new, and theysimply lacked the resources that enabled them to quickly zero in on the exactdesign aspects needed for deep, tight, accurate bass response.

It canbe convincingly argued that the benefits of extended bass of vented over closedbox is actually of more benefit than sealed’s lower group delay, since eventhough the ultimate group delay of vented systems may be higher, it is usually deferredto a lower frequency where it is of less audible importance.

Thesealed box AR-3a and AR-LST have a Q of .707, which is optimally damped. TheAR-9 has a Q of .5, bordering on critically damped. The choice of these Qvalues by the designer results in a very flat, non-peaked response down to thesystem’s –3dB point, which implies a very low group delay. The 9 actuallybegins to roll off a little before its 3dB down point, but it’s an excellentdesign choice, because the 9’s natural 3dB down point is so low anyway (anhonest 28 Hz!) by virtue of its two 12-inch drivers’ 18Hz free-air resonanceand the amount of bass energy the system produces with that big enclosure (afloor standing cabinet of over 4 cubic feet). By choosing a Q of .5 thedesigners have elected to intentionally “throw away” a little bass energy—whichthey can easily afford because the 9 has so much to begin with—in exchange forsuper tight, clean bass. A lower Q means greater damping, and lower groupdelay.

SystemQ comparison in acoustic suspension loudspeakers

AR-9with Dual 12-inch Woofers

This notion of low groupdelay is also presented by another well-respected source, Siegfried Linkwitz onhis website. In a feature entitled “Frontiers,” in section F under theheading “Group delay and transient response,” he states: '…I am notcertain what happens in the range below 100 Hz and I have strong suspicionsthat this is the region where delay distortion is audible. It is also theregion where delay really accumulates via vented and bandpass woofers, and thegreat numbers of dc blocking capacitors in the signal chain from microphone tospeaker terminal.'

The delay issue invented systems is particularly important around the “handoff frequency” (thepoint in a vented system at which the port’s LF output begins to dominate overthe woofer’s actual output) because the backwave of the woofer that exitsthrough the vent is literally “delayed” some amount of time relative to the directfrontal output from the woofer. Below that frequency, the port’s outputdominates over the woofer and therefore any “delay” relative to the woofer isinsignificant due to the relationship of the speed of sound (1130 feet/second)to the very small distances involved (perhaps a 12”-long port internal port).Nonetheless, some highly-accomplished and well-regarded audio engineers (suchas the late, brilliant Peter Mitchell) have theorized that these admittedlysmall differences in group delay in favor of acoustic suspension are acontributing factor to the long-held view that a properly-executed acousticsuspension speaker—like the AR-11 or ADS 1290—has bass best described as “fast,tight and clean.”

It needs to be pointedout that most of today’s high-profile speaker engineers do not share Mitchell’scontention that group delay is a major contributing factor to the audiblecharacter and quality of loudspeaker bass reproduction. The general feeling isthat group delay is not anywhere near as audible to the untrained ear asMitchell implies and there are many other factors that dominate perceived bassquality, such as frequency response, distortion and audible mechanical artifactssuch as voice coil bottoming against the backplate, surround “snap” at veryhigh SPL levels and port chuffing in vented loudspeakers. Nonetheless, thegroup delay issue is being presented here because its impact on audible basscharacter is a plausible possibility, especially being presented by such ahighly-educated, scientifically-minded expert like Mitchell.

Drivers Sealed Unit Parts Port Devices List

Sealing the Ports of Vented Loudspeakers

Quite frankly, there may be valid reasons as to why some manufacturers these days provide port plugs. In a full-range tower, making a ported tower into a “sealed” system changes its low-frequency rolloff from 24 dB/oct to 12 dB/octave, while also raising the system’s effective -3 dB LF limit. So a ported pair of $1500 towers that get down to 45 Hz all by themselves with a very steep rolloff below that now go to, say 70 Hz when sealed, with a much more gradual rolloff. This higher -3 dB point and shallower rolloff can very well be a much better blend when used with a subwoofer and a 60-80 Hz sub crossover. In a case like this, the goal of “sealing” the tower is not to produce a full-range acoustic suspension speaker, but instead, to create a more flexible speaker that works better in conjunction with a subwoofer.

Likewise, there can be good reasons for offering ported and sealed options in a subwoofer. Make no mistake, a ported sub is optimized to be a ported sub. It will have its deepest LF extension and greatest SPL capability when used as a wide-open unrestricted ported system. But modern-day high-powered ported “super subs” can easily overwhelm a medium or small room with excessive output, especially if it’s located too close to reinforcing room boundaries, like in or near a corner. Plugging the port (or one or both, if it’s dual-ported) will reduce the sub’s LF SPL output and ultimate frequency extension, which will often result in a better, smoother in-room frequency response. Sometimes, these subs have a choice of internal EQ shapes, depending on whether port plugs are used or not, thus ensuring good response and accurate sound.

The Appeal of True Acoustic Suspension Speakers

However, the contention here is that subwoofer designers are missing the boat by not recognizing what makes for a truly excellent acoustic suspension system, designing drivers that have the correct Q, compliance and FAR and utilizing that driver in an advantageous way in a self-powered system. Consider this:

Many of today’s “sealed” powered subwoofers have an internal cabinet volume of around 1.5 cu. Ft. What a coincidence—1.5 cu. ft. happens to be the exact same internal cabinet volume of perhaps the most famous and highly-regarded acoustic suspension speakers of all time: AR’s AR-3, 3a, 11 and 10π series. These 12-inch 3-way speakers achieved a -3dB down point of 35 Hz, which all by itself is significantly lower than the low E on an electric bass (41.2Hz). These speakers were legendary in their day for clean, powerful low bass.

AR-11 spec sheet showing 1.48 cu. ft. enclosure volume, 18 Hz woofer FA

Do the math: If an AR-3a or AR-11 is -3 dB at 35Hz, with a rolloff of 12 dB/oct, that means it will only be down 15 dB at 17 Hz. With a very modest LF boost of about 5 dB centered around 30Hz, the 3a/11 is flat (-3 dB) down into the low-mid 20’s, with useful response still available at 20 Hz.

Today’s best subwoofer drivers from top manufacturers far exceed the old AR and KLH woofers in terms of heavy-duty construction, greater power handling, higher-temperature adhesives, longer excursion, bumped-out backplates, and so on. Today’s woofers are designed for digital LF inputs at levels and frequencies AR’s and KLH’s designers could never have foreseen. A modern version of the 3a’s woofer could tolerate 5 dB of boost with its eyes closed.

But quite unlike today’s woofers, the Q and FAR of those old AR and KLH woofers were optimized for their small sealed enclosure. The key is to look at the FAR of the woofer. The AR 12-inch woofer—essentially unchanged from the AR-3 of 1958 right through the AR-9Lsi of 1984—had an FAR of around 18 Hz. Peruse the pages of Parts Express or Madisound or any other raw driver supplier and you’ll be hard-pressed to find many 12-inch woofers—even so-called subwoofer drivers—with an FAR much below 25-30 Hz. The driver’s FAR really tells most of the story, because in order to have a really low FAR, the driver’s compliance has to be very high, the cone mass also has to be appropriately high and the driver’s magnetic strength has to be correct for the application intent of the driver. So if you look at the FAR, you can pretty much tell if it’s going to work well in an acoustic suspension system. There are very few good offerings, which perfectly mirrors the fact that there is an almost complete lack of real acoustic suspension subwoofers (or full-range speakers either, for that matter) on the market today. Remember, we’re not talking merely “sealed.” We’re talking real acoustic suspension, where the drivers have extremely high compliance and low FAR and the air spring in the box—not the driver’s mechanical suspension—is providing the great majority of the restoring force.

SB Acoustics SB34SWPL-76-4 12' Subwoofer Driver

But this is far more typical of today’s subwoofer drivers: FAR of 28 Hz and a Qts of .48. Beautiful driver—beefy, well-made,aluminum cone, no doubt a monster of a woofer, as long as it’s mountedin a vented cabinet of the appropriate size (3.0 cu. ft. or more). Butas physically “impressive” as this driver is, it would never reach -3 dBinto the low 30-Hz range passively—unaided by rather drasticresponse-shaping electronic EQ—in an enclosure of 1.5 cu. ft.

Drivers such as these with an FAR above 23-30Hz are simply unsuited to being used in true, optimized acoustic suspension systems. If they are used in a sealed system, excessive electronic EQ is required to achieve a reasonable LF extension because the “organic” (passive) response of a sealed system using a driver like this in an enclosure of 1.5-2.0 cu. ft. will have a -3 dB point of 40-60 Hz at best. It’ll take a lot of amplifier power to EQ its way down to 20 Hz, power that will no longer be available for overall system SPL. Remember, every additional 3 dB of SPL requires a doubling of amplifier power. The difference between 6 dB of LF EQ and 12 dB of LF EQ is 4 times the power! Like former president John Adams said, “Facts are inconvenient things.”

The on-board power in a subwoofer (an expensive and quite finite commodity, after all) is being “wasted” on EQ because the system’s passive response gives up the ghost at 55 Hz instead of 35 Hz. And you can be sure these new woofers—optimized for vented cabinets—wouldn’t even be in a nearby universe of -3 dB at 35 Hz in a sealed enclosure as small as 1.48 cu. ft.

The drivers used in today’s “sealed” subwoofers are not acoustic suspension drivers. The majority of the restoring force is not provided by the air spring in the subwoofer’s enclosure, as would be the case in a true acoustic suspension system using a very high-compliance driver. In fact—amazingly, unbelievably—many of these manufacturers use the exact same driver in both the ported and sealed versions of their subwoofer. Since it is used in the vented system (and that system performs so well), one can safely assume the driver’s Q is well above .4-.45. That means that it is optimized for ported use and badly mismatched for a sealed application, or that both of the applications are unsatisfying compromises. A driver is either optimized to be a ported driver or an acoustic suspension driver. It can’t be both.

But….if these manufacturers had optimized a second version of their woofer specifically for use as a true acoustic suspension driver, what a truly great product that would be. Less LF EQ would be necessary for the system to reach the same-3 dB LF point than is currently the case with a high-Q woofer in a small sealed enclosure, so more power would be available for sheer output. The system would play louder with the same bass extension. Or, you could make the enclosure even smaller, which would require a bit more EQ, probably on the order of what those actual small sealed subs are using now. So a true acoustic suspension compact subwoofer would either play louder at the same size or play as loud, but in a smaller enclosure. Either way, it’s a better product in my opinion.

The only obstacle to getting a great product like this is that the engineers would have to know the ins and outs of real acoustic suspension design. Which they don’t (or they choose to ignore, unfortunately). So instead of great small acoustic suspension subs that will play loud and low from a small enclosure, with great transient response, low THD over their usable band and a very gradual 12 dB/oct. rolloff—perfect for real-life family rooms of, say, 2000 cu. ft, what we have instead are ‘sealed sub’ compromises, which are merely very good products.

Drivers Sealed Unit Parts Port Devices Gigabit

Editorial Note about Sealed vs Acoustic Suspension Enclosure by James Larson:

Drivers Sealed Unit Parts Port Devices For Sale

As excursion for bass drivers have grown larger, high compliancesuspension of the type needed for acoustic suspension design becomesmore difficult to engineer for reliable performance. The thinsuspension components needed for high compliance suspension aresusceptible to self-destruction at high excursions, not to mentionincreased distortion from rocking modes and deformation. Furthermore,air doesn't have enough damping force against the effects of progressivesuspension for high excursions. At high excursions, the suspension mustbe able to damp itself, and that means that it has to have lowercompliance than an acoustic suspension system would call for. Acousticsuspension was a more viable solution in older eras of loudspeakerdesign when one-way linear excursion could be around 5mm, but moderndesigns aim for much larger excursions where high compliance suspensionsbecome impractical.

This article has been technically vetted by several veryexperienced and highly-respected acoustics engineers:

- Mark Nazar—In his distinguished career spanning more than fourdecades, Mark has held senior Project Engineer, Transducer Engineer and SystemsEngineer positions at major companies such as McIntosh, Apogee, AcousticResearch and Boston Acoustics.

Gerry Sheetoo—Gerry was a loudspeaker systems engineer for closeto 20 years at Boston Acoustics, where he was directly responsible for the designand voicing of several of the company’s (and thus the audio industry’s)best-selling and most highly-reviewed music and home theater speakers, coveringall types from acoustic suspension to vented to infinite baffle, both activeand passive designs.

Paul Ceurvels—Paul was head Electrical Engineer at NAD USA andthen went on to become Senior Design Engineer at Atlantic Technology until hisretirement in 2017. He has extensive experience in all aspects of productdesign and engineering, from electrical to acoustics to mechanical tomaterials. Eating lunch every day at his desk, he’d download the latesttechnical data sheets and research papers to read for entertainment, “just tokeep tabs on what those sons-of-b’s are up to.”

Drivers Sealed Unit Parts Port Devices Inc

Please share your thoughts in the related forum thread below aboutAcoustic Suspension speakers and whether or not you think they deserve acome back.